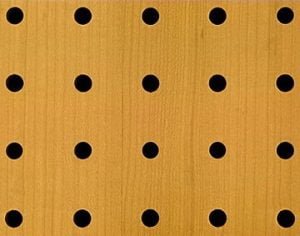

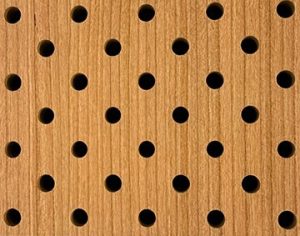

Perforated Wood Panels for Optimal Sound Control

MCM Acoustical’s Perforated Wood Panels feature a natural wood surface complemented by 6, 8, or 10mm parallel or staggered perforations. The standard spacing for these perforations are 16 or 32mm. These panels are designed to provide optimal acoustical performance with a standard 5/8″ Fire-Rated MDF core, other thicknesses are also available.

Downloads

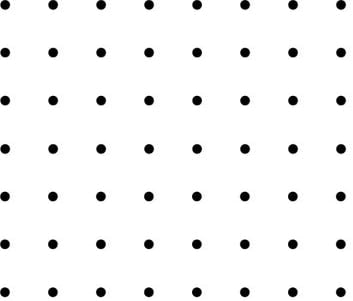

Parallel Perforation

6mm

Parallel PP-P-6-32

2.76% Opening

8mm

Parallel PP-P-8-32

4.91% Opening

10mm

Parallel PP-P-10-32

7.67% Opening

6mm

Parallel PP-P-6-16

11.04% Opening

8mm

Parallel PP-P-8-16

19.63% Opening

10mm

Parallel PP-P-10-16

30.66% Opening

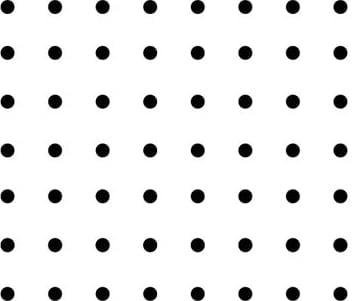

Staggered Perforation

6mm

Staggered PP-S-6-32

5.17% Opening

8mm

Staggered PP-S-8-32

9.20% Opening

10mm

Staggered PP-S-10-32

14.37% Opening

6mm

Staggered PP-S-6-16

22.08% Opening

8mm

Staggered PP-S-8-16

39.25% Opening

Features

Dimensions:

The Perforated Wood Panels can be manufactured to the desired size, with shop drawings produced by MCM Acoustical, thereby requiring no field cutting for faster installation. MCM Acoustical’s leading production capabilities make the largest panels in the industry: 5′ x 10′ (1.5M x 3M). The Planks are produced in a standard width of 192mm (7 9/16″) and a standard length of 2438mm or 3048mm (8′ or 10′). Custom plank widths and lengths are also available.

Veneers:

The Perforated Wood Panels can be customized in a variety of wood veneers. MCM Acoustical lays up its own veneer. For panels, we offer slip-matched, book-matched, or custom lay-up options, and for planks, random-matched lay-up choices are available.

Finishes:

The Perforated Wood Panels can be finished in standard clear lacquer or can be custom stained to match a control sample. The Panels & Planks can also be painted.

Fire

Fire

Performance

The Perforated Wood Panels are Class A fire rated interior wood finish products as per ASTM E84 and CAN/ULC S102 tested in an accredited NVLAP test facility as a finished composite product using Class A individual components.

Acoustic

Acoustic

Performance

In addition to the Perforated face of the panel, the MDF core is perforated to improve sound absorption. A black mat is laminated to the rear of the product to create a substantial acoustic performance of up to 1.05 NRC.

Acclimatization

Acclimatization

Like any other architectural natural wood products, all MCM Acoustical products are to be acclimatized inside a controlled interior environment for at least 75 hours before installation. During storage prior to installation, during installation, and after installation the relative humidity level of 35% -55% and temperature range of 20°-27°C (68°-81°F) must be maintained.

Sustainability

Sustainability

FSC Certified

70.8% pre-consumer recycled content Declare label CDPH VOC Certified

Indoor Air

Indoor Air

Quality

The Perforated Wood Panels are certified Clean Air Gold and meet the CDPH Standard VOC emissions.

Sound

Sound

Absorption

Number in the mounting designation is the airspace behind/above the panel in millimeters.

| Mounting | Backing | Frequency 125 Hz | Frequency 250 Hz | Frequency 500 Hz | Frequency 1000 Hz | Frequency 2000 Hz | Frequency 4000 Hz | NRC | SAA |

|---|---|---|---|---|---|---|---|---|---|

| Type E400 (15 ¾”) | N/A1″ Thick FG2″ Thick FG | 0.770.660.63 | 0.930.810.74 | 0.730.810.90 | 0.750.950.95 | 0.750.920.93 | 0.670.800.80 | 0.800.850.90 | 0.790.860.87 |

| Type F50 (2″) | 2″ Thick FG* | 0.68 | 0.87 | 0.94 | 0.90 | 0.87 | 0.72 | 0.90 | 0.90 |

| Type F25 (1″) | N/A1″ Thick FG* | 0.080.37 | 0.130.66 | 0.350.98 | 0.750.90 | 0.830.85 | 0.480.72 | 0.500.85 | 0.510.85 |

| Type F5 (3/16″) | N/A | 0.06 | 0.08 | 0.10 | 0.17 | 0.65 | 0.57 | 0.25 | 0.25 |

(*) 6-7 PCF 1″ or 2″ Fiberglass

Finishes

Other veneers are available upon request. If you wish to specify a wood species that is not mentioned on the Finishes page, kindly contact MCM Acoustical to confirm its consistent availability. All veneers can be custom stained. Planks can also be painted.